Views: 0 Author: Site Editor Publish Time: 2025-09-09 Origin: Site

Conveyor belts are the backbone of industrial transport systems. But which type is best for your needs? Choosing the right conveyor belt is crucial for efficiency and cost-effectiveness. In this post, you'll learn the key differences between rubber conveyor belts and PVC conveyor belts. Discover which one suits your industry best.

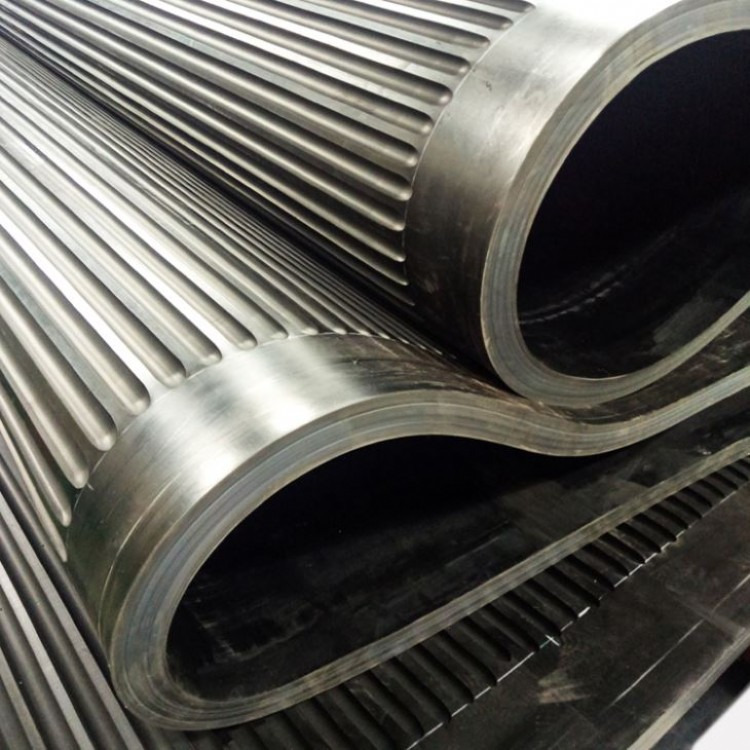

A rubber conveyor belt is a type of conveyor belt made primarily from natural or synthetic rubber. It consists of several layers, known as plies, which are reinforced with materials like fabric or steel cords to enhance strength and durability. This construction makes rubber belts particularly robust, allowing them to handle heavy loads and endure tough industrial environments. Rubber conveyor belts are widely used in industries where materials are abrasive, heavy, or transported under high temperature conditions.

Rubber conveyor belts are known for several key features:

High Durability and Strength: They resist wear and tear caused by abrasive materials, making them ideal for mining, construction, and metal processing.

Excellent Flexibility: Despite their strength, rubber belts remain flexible, allowing them to absorb shocks and impacts during material handling.

Heat and Fire Resistance: Special grades of rubber belts, such as heat-resistant (HR) and fire-resistant (FR) types, can tolerate temperatures up to 200°C, suitable for harsh environments.

Good Grip and Friction: Rubber surfaces provide superior grip, reducing slippage even on inclined conveyors.

Impact Absorption: The elasticity of rubber helps absorb mechanical shocks from heavy or fast-moving materials, protecting both the belt and transported goods.

Oil and Chemical Resistance: Certain rubber belts are designed to withstand exposure to oils and chemicals, though their resistance varies depending on the rubber compound used.

Rubber conveyor belts excel in heavy-duty industries requiring toughness and reliability:

Mining: Transporting ores, coal, and rocks where abrasion and heavy loads are common.

Quarries: Handling gravel, sand, and other rough materials.

Cement Plants: Withstanding high temperatures and abrasive environments.

Metal Processing: Moving hot, heavy metal parts in manufacturing.

Construction: Carrying building materials under tough conditions.

Furnace and Glass Manufacturing: Using heat-resistant belts to transport hot products.

Because of their durability and adaptability, rubber conveyor belts are preferred where performance and longevity are critical, even if their initial cost and maintenance needs are higher than alternatives.

Tip: Choose rubber conveyor belts for applications involving heavy loads, high temperatures, or abrasive materials to ensure long-lasting performance and reduced downtime.

A PVC conveyor belt is made from polyvinyl chloride, a type of thermoplastic polymer. It often has fabric layers inside for added strength and flexibility. These belts are lighter and thinner than rubber belts, making them easier to handle and install. PVC belts are popular in industries where hygiene, chemical resistance, and cost-effectiveness are important. Because PVC is a synthetic plastic, these belts resist water, moisture, and many chemicals better than rubber.

PVC conveyor belts offer several key benefits:

Lightweight and Flexible: Their lower density means less weight, which reduces energy use and simplifies installation.

Cost-Effective: PVC belts generally cost less upfront than rubber belts, making them attractive for budget-conscious businesses.

Chemical and Moisture Resistant: They resist acids, solvents, alcohol, and alkalis well, making them suitable for environments with exposure to these substances.

Easy to Clean and Hygienic: Smooth surfaces prevent dirt buildup and bacterial growth, ideal for food processing, pharmaceuticals, and packaging.

Waterproof: PVC does not absorb moisture, so these belts are resistant to mold and mildew.

Low Maintenance: Their durability in mild conditions means less frequent repairs and downtime.

However, PVC belts have limitations. They do not perform well in high-temperature settings, usually tolerating up to about 60°C before softening or deforming. They also have lower abrasion resistance and tensile strength compared to rubber belts, making them less suited for heavy or sharp materials.

PVC conveyor belts are best suited for light to medium-duty tasks where cleanliness and chemical resistance matter:

Food Processing: Transporting baked goods, packaged foods, and dairy products where hygiene is critical.

Pharmaceuticals: Moving medicines and medical supplies in cleanrooms and controlled environments.

Packaging: Handling boxes, cartons, and lightweight goods in warehouses and distribution centers.

Electronics Manufacturing: Conveying delicate components where static resistance and cleanliness are important.

Light Assembly Lines: Suitable for industries where loads are not heavy and materials are not abrasive.

In these settings, PVC belts help maintain product quality and reduce contamination risks. Their ease of cleaning and resistance to moisture and chemicals make them a practical choice.

Rubber conveyor belts excel in tough environments. Their natural elasticity and reinforced layers help them resist wear from abrasive materials like rocks, ores, and heavy metals. They withstand impacts and rough handling better than most other belts. This makes them ideal for mining, construction, and heavy manufacturing, where belts face constant abrasion and mechanical stress.

PVC belts, on the other hand, perform well in less demanding settings. They resist moisture and many chemicals but wear faster when exposed to sharp or abrasive materials. PVC can degrade quicker under continuous heavy loads or harsh impacts. So, in environments where materials are light to medium weight and less abrasive, PVC belts hold up well. But for rugged conditions, rubber belts last longer.

Rubber belts offer superior tensile strength. Their multi-ply construction, often reinforced with steel cords or fabric, allows them to carry heavy loads without stretching or breaking. This strength is critical in industries like mining or metal processing, where conveyors transport bulky, dense materials.

PVC belts have lower tensile strength. They work best for light to medium loads, such as packaged goods or food items. Their fabric reinforcement provides some strength, but they are not designed for heavy, continuous stress. Using PVC belts for heavy-duty tasks risks premature wear or failure.

Rubber belts are highly flexible, which helps them absorb shocks and impacts during transport. This flexibility reduces damage to both the belt and the materials being conveyed. It also allows rubber belts to bend around pulleys and rollers smoothly, minimizing stress points.

PVC belts are less elastic and more rigid. While they can handle moderate bending, they do not absorb shocks as effectively. This makes them less suitable for applications with sudden impacts or heavy vibrations.

PVC conveyor belts generally outperform rubber belts in chemical resistance. PVC's synthetic plastic makeup resists acids, solvents, alcohols, and alkalis better than rubber. This makes PVC belts ideal for industries like food processing, pharmaceuticals, and packaging, where exposure to chemicals is common. Rubber belts, though resistant to some oils and chemicals, can degrade or swell when exposed to harsh substances over time. For example, rubber may deteriorate faster if frequently in contact with oils or certain chemicals, limiting its use in chemical-heavy environments.

Rubber conveyor belts excel in high-temperature environments. Special rubber grades can withstand temperatures up to 200°C, making them suitable for heavy industries like mining, metal processing, and cement manufacturing. They maintain strength and flexibility under heat stress, preventing deformation or failure.

PVC belts, however, have lower temperature tolerance, typically up to 60°C. Above this, PVC softens, warps, or cracks, limiting its use in high-heat applications. This makes PVC belts unsuitable for furnace operations or hot product handling. In cooler environments, PVC performs well but should be avoided where heat exposure is frequent or intense.

Environmental conditions also affect belt performance. Rubber belts resist UV rays, ozone, and outdoor weather better than PVC. Prolonged sunlight exposure can cause PVC belts to degrade faster, leading to brittleness and cracking. Moisture absorption is another factor—PVC belts do not absorb water, so they resist mold, mildew, and moisture-related damage better than rubber belts, which can absorb moisture and may require more maintenance in wet conditions.

In cold environments, rubber belts may become stiff or brittle, while PVC belts maintain flexibility better but still face limitations in extreme temperatures. Choosing the right belt depends on balancing chemical exposure, temperature range, and outdoor conditions.

When choosing between rubber and PVC conveyor belts, initial cost is a key factor. PVC belts generally cost less upfront. Their manufacturing process and materials are cheaper, making them attractive for businesses with tight budgets or light-duty needs. Installation costs tend to be lower as well since PVC belts are lighter and easier to handle.

Rubber conveyor belts, however, require a higher initial investment. Their complex construction, including multiple rubber layers and reinforcements, drives up production costs. Installation can also be more labor-intensive due to their weight and thickness. Despite this, rubber belts often prove more cost-effective over time. Their durability and resistance to wear reduce the need for frequent replacements, saving money on downtime and repairs.

Maintenance needs differ significantly between the two belt types. PVC belts require less routine maintenance in mild environments. Their resistance to moisture, chemicals, and dirt buildup means fewer cleaning cycles and less frequent repairs. This makes PVC belts ideal for industries like food processing or packaging, where hygiene and minimal downtime are priorities.

Rubber belts demand more attention, especially in harsh or abrasive settings. They may need regular inspections for wear, tears, or damage caused by heavy loads and impact. Periodic cleaning and conditioning can help maintain their flexibility and prevent cracking. However, their robust design often means they can endure longer between major repairs, making maintenance worthwhile for heavy-duty industries.

The choice between PVC and rubber belts often depends on the industry and application demands:

Light to Medium-Duty Industries: PVC belts offer a cost-effective solution with low maintenance and easy cleaning. Industries such as pharmaceuticals, food processing, and light packaging benefit from their affordability and hygiene features.

Heavy-Duty Industries: Rubber belts justify their higher cost through superior durability and longevity. Mining, construction, metal processing, and cement plants rely on rubber belts to handle abrasive materials, high temperatures, and heavy loads without frequent replacements.

Energy Consumption: PVC belts, being lighter, reduce conveyor system energy use. This can lower operational costs over time, especially in large-scale or continuous operations.

Downtime Costs: Rubber belts’ resilience minimizes unexpected breakdowns in demanding environments, reducing costly production halts.

Rubber conveyor belts thrive in heavy-duty industries where durability and strength are crucial. They handle abrasive, heavy, or hot materials well, making them ideal for:

Mining: Transporting ores, coal, and rocks where belts face constant wear.

Quarries: Moving gravel, sand, and rough materials that can damage lighter belts.

Cement Plants: Withstanding high temperatures and abrasive dust.

Metal Processing: Carrying hot, heavy metal parts in manufacturing lines.

Construction: Handling bulky building materials under tough conditions.

Glass and Furnace Manufacturing: Using heat-resistant belts for hot product transport.

Rubber belts provide superior grip and shock absorption, reducing slippage and damage during transport. Their ability to endure harsh environments ensures long-lasting performance even under heavy mechanical stress.

PVC conveyor belts are best for light to medium-duty applications where hygiene, chemical resistance, and cost efficiency matter. They excel in industries such as:

Food Processing: Transporting baked goods, dairy, and packaged foods while meeting strict cleanliness standards.

Pharmaceuticals: Operating in cleanrooms where easy sanitation and chemical resistance are essential.

Packaging: Moving lightweight cartons, boxes, and products in warehouses and distribution centers.

Electronics Manufacturing: Conveying delicate components in controlled environments.

Light Assembly Lines: Handling non-abrasive materials and moderate loads efficiently.

PVC belts’ smooth surfaces resist moisture and chemicals, preventing contamination and reducing cleaning time. Their lighter weight also lowers energy use and simplifies installation.

Mining Operation: A large mine uses rubber conveyor belts to transport heavy ore across rugged terrain. The belts withstand abrasion and high temperatures, minimizing downtime despite harsh conditions.

Food Packaging Plant: A bakery employs PVC conveyor belts for moving packaged goods. The belts’ easy cleaning and chemical resistance help maintain hygiene and reduce maintenance costs.

Metal Foundry: A steel plant relies on heat-resistant rubber belts to move hot metal parts safely. The belts’ flexibility and durability prevent frequent replacements despite extreme heat exposure.

Pharmaceutical Manufacturer: A drug company uses PVC belts in cleanroom assembly lines. The belts’ moisture resistance and smooth surfaces support strict sanitary requirements.

These examples highlight how choosing the right belt type can optimize production efficiency and reduce operational costs.

Rubber conveyor belts excel in durability, strength, and high-temperature resistance, ideal for heavy-duty industries. PVC belts offer chemical resistance, hygiene, and cost-effectiveness, suited for light-duty tasks. Choose rubber for abrasive, hot materials; PVC for clean, chemical-resistant applications. For quality solutions, consider Qingdao Hwation Rubber Co.,Ltd. Their products provide exceptional value through robust construction and adaptability, ensuring reliable performance in demanding environments.

A: A rubber conveyor belt is used for transporting heavy, abrasive materials in industries like mining, construction, and metal processing, where durability and heat resistance are crucial.

A: Choose a rubber conveyor belt for its superior strength, flexibility, and heat resistance, making it ideal for heavy-duty applications and harsh environments compared to PVC belts.

A: Rubber conveyor belts generally have a higher initial cost but offer long-term savings due to their durability and reduced need for replacements, unlike more affordable PVC belts.

A: Rubber conveyor belts offer high durability, excellent grip, impact absorption, and heat resistance, making them suitable for demanding industrial applications.

A: To troubleshoot rubber conveyor belts, check for wear, tears, or misalignment, ensure proper tension, and maintain regular inspections to prevent breakdowns in heavy-duty environments.