| Availability: | |

|---|---|

| Quantity: | |

Technical Parameters

| Belt Type | ST630 | ST800 | ST1000 | ST1250 | ST1600 | ST2000 | ST2500 | ST3150 | ST3500 | ST4000 | ST4500 | ST5000 | ST5400 | ST6300 | ST7000 | ST7500 |

| Tensible Strength(N/mm) | 630 | 800 | 1000 | 1250 | 1600 | 2000 | 2500 | 3515 | 3500 | 4000 | 4500 | 5000 | 5400 | 6300 | 7000 | 7500 |

| Max.Diam.of Cord (mm) | 3.0 | 3.5 | 4.0 | 4.5 | 5.0 | 6.0 | 7.2 | 8.1 | 8.6 | 8.9 | 9.7 | 10.9 | 11.3 | 12.3 | 13.5 | 15.0 |

| Pitch of Cord(mm) | 10 | 10 | 12 | 12 | 12 | 12 | 15 | 15 | 15 | 15 | 16 | 17 | 17 | 18 | 19 | 21 |

| Top Rubber Cover Thickness(mm) | Customized According to Customer Requirements | |||||||||||||||

| Bottom Rubber Cover Thickness(mm) | Customized According to Customer Requirements | |||||||||||||||

| Belt Width (mm) | Nº of steel cords | |||||||||||||||

| 800 | 75 | 75 | 63 | 63 | 63 | 63 | 50 | 50 | 50 | |||||||

| 1000 | 95 | 95 | 79 | 79 | 79 | 79 | 64 | 64 | 64 | 64 | 59 | 55 | 55 | 54 | 49 | 45 |

| 1200 | 113 | 113 | 94 | 94 | 94 | 94 | 76 | 77 | 77 | 77 | 71 | 66 | 66 | 63 | 59 | 54 |

| 1400 | 133 | 133 | 111 | 111 | 111 | 111 | 89 | 90 | 90 | 90 | 84 | 78 | 78 | 74 | 69 | 63 |

| 1600 | 151 | 151 | 126 | 126 | 126 | 126 | 101 | 104 | 104 | 104 | 96 | 90 | 90 | 85 | 80 | 72 |

| 1800 | 171 | 143 | 143 | 143 | 143 | 114 | 117 | 117 | 117 | 109 | 102 | 102 | 96 | 90 | 82 | |

| 2000 | 159 | 159 | 159 | 159 | 128 | 130 | 130 | 130 | 121 | 113 | 113 | 107 | 101 | 91 | ||

| 2200 | 176 | 141 | 144 | 144 | 144 | 134 | 125 | 125 | 118 | 111 | 100 | |||||

| 2400 | 193 | 155 | 157 | 157 | 157 | 146 | 137 | 137 | 129 | 121 | 109 | |||||

| 2600 | 209 | 168 | 170 | 170 | 170 | 159 | 149 | 149 | 140 | 131 | 119 | |||||

| 2800 | 230 | 184 | 184 | 184 | 184 | 171 | 161 | 161 | 151 | 142 | 129 | |||||

| 3000 | 247 | 198 | 198 | 198 | 198 | 185 | 174 | 174 | 148 | 152 | 138 | |||||

| 3200 | 264 | 211 | 211 | 211 | 211 | 198 | 186 | 186 | 158 | 162 | 147 | |||||

| Test Items | Property Indexes | |||||||||||||||

| GB9770-2001 | DIN22131 | |||||||||||||||

| D | H | L | P | W | X | Y | Z | More other grades can produce according to customer requirements. | ||||||||

| Tensile Streng | Mpa≥ | 18 | 25 | 20 | 14 | 18 | 25 | 20 | 15 | |||||||

| Elongation at Break | %≥ | 400 | 450 | 400 | 350 | 400 | 450 | 400 | 350 | |||||||

| Abrasion | ≤mm³ | 90 | 120 | 150 | 200 | 90 | 120 | 150 | 250 | |||||||

Product Advantage

1. High Tensile Strength: The steel cord conveyor belt boasts exceptional tensile strength, making it ideal for conveying heavy and bulk materials over long distances. The incorporation of strong steel cords within the belt ensures superior load-carrying capacity, reducing the risk of belt deformation and enhancing overall efficiency.

2. Enhanced Durability: This conveyor belt exhibits remarkable resistance to wear, tear, and impact, significantly extending its operational lifespan. The innovative manufacturing process and the use of high-quality materials ensure that the belt can withstand harsh environments and heavy-duty applications with minimal maintenance requirements.

3. Excellent Flexibility: Despite its robust construction, the steel cord conveyor belt maintains impressive flexibility, allowing it to adapt to various pulley diameters and curvature requirements without compromising its structural integrity. This feature guarantees smooth and consistent material transportation, reducing downtime and increasing productivity.

4. Advanced Splicing Technology: The steel cord conveyor belt incorporates cutting-edge splicing techniques that ensure strong and reliable joints between steel cords. This minimizes the risk of splice failure, contributing to a safer working environment and improved operational efficiency.

5. Superior Impact Resistance: The belt's unique design and steel cord arrangement provide exceptional impact resistance, protecting the belt from damage caused by sharp or heavy materials during loading and unloading processes. This resilience enhances the overall reliability of the conveyor system.

6. High Temperature Resistance: With the ability to withstand elevated temperatures, the steel cord conveyor belt is suitable for applications in industries like mining, steel, and cement, where materials are conveyed at high temperatures. This thermal stability ensures consistent performance and minimizes the risk of belt deformation under extreme conditions.

Product Uses

Application Groups : General Purpose, Heat Resistance, Fire Resistance, Abrasion Resistance, Oil Resistance, Acid/Alkali/Cold Resistance

Product Uses:

Mining: Efficiently transport coal, ore, and minerals over long distances in mining operations, ensuring safety and productivity.

Construction: Handle construction materials like sand and cement on job sites, streamlining building processes.

Manufacturing: Optimize production lines, moving materials and products in industries like automotive and aerospace.

Ports: Indispensable for loading and unloading cargo onto ships, contributing to efficient logistics.

Agriculture: Facilitate grain, seed, and fertilizer handling, improving agricultural operations.

Recycling: Essential in recycling facilities for effective waste management and resource conservation.

Power Generation: Transport coal and biomass in power plants, ensuring continuous energy production.

Warehousing: Streamline material movement in distribution centers, enhancing operational efficiency.

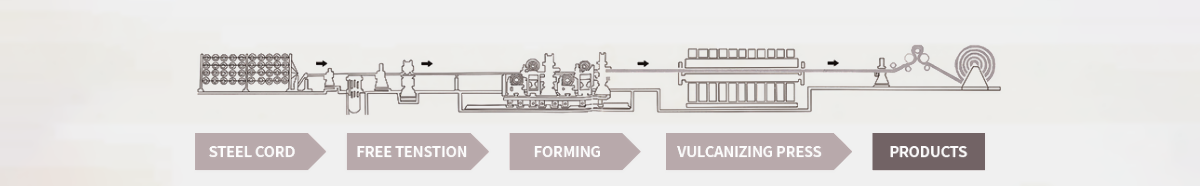

Production Process

FAQ

1. What is the typical warranty period for steel cord conveyor belts?

The warranty period for steel cord conveyor belts usually ranges from 12 to 36 months, depending on the manufacturer and the specific belt type. This warranty covers defects in materials and workmanship during normal usage.

2. How long does it take to deliver steel cord conveyor belts after placing an order?

Delivery times for steel cord conveyor belts may vary based on the order quantity and the manufacturer's production schedule. Generally, it takes 4 to 8 weeks for standard orders, but expedited options may be available upon request.

3. Are there any special maintenance requirements during the warranty period?

During the warranty period, it is crucial to follow the manufacturer's recommended maintenance procedures. Regular inspections, proper tensioning, and adhering to operating guidelines are necessary to ensure the warranty remains valid and to maximize the conveyor belt's performance and lifespan.