FRP stands for Fiberglass Reinforced Plastic—a powerful composite material used across industries like automotive, aerospace, construction, and marine. It’s known for being lightweight, durable, and super tough. You might also see it referred to as Fibre Reinforced Polymer (British English) or Fiber Reinforced Plastic (American English). Same thing, just different spellings.

But why should you care? Because FRP shows up everywhere—bridges, boats, buildings, buses, even your gym equipment. If you want a material that resists rust, handles stress, and stays light on its feet, this is it. We’re diving deep into what FRP really means, what it’s made of, where it’s used, and why industries love it.

In science and engineering, FRP means Fiberglass Reinforced Plastic or Fibre Reinforced Polymer. It’s a composite material, which means it’s made by combining two or more materials to form something better.

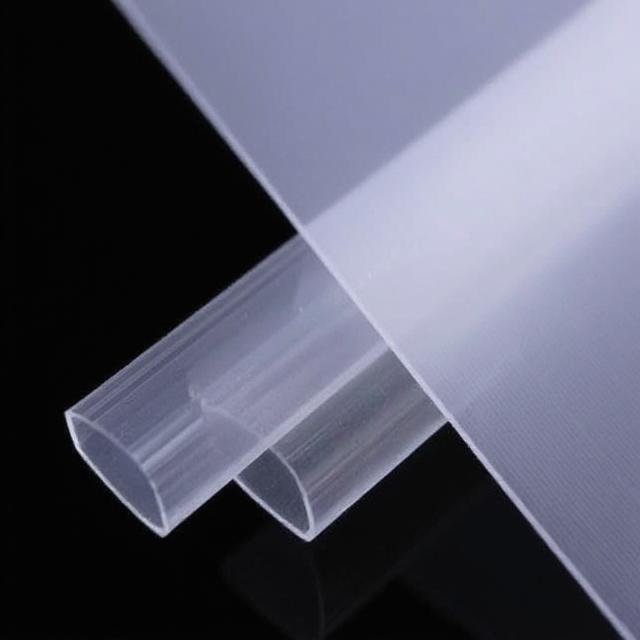

Here’s how it works: strong, stiff fibers (usually glass) are embedded in a plastic base (called a matrix). Together, they create something tougher and more versatile than either material on its own.

FRP = fibers + plastic matrix. Simple formula. Big performance.

The fibers give strength. The plastic holds it all together. Together, they build parts that are strong, light, and flexible. They can take heat, stress, and corrosion like champs.

Let’s break it down visually:

| Component | Role in FRP | Examples |

|---|---|---|

| Fibers | Provide strength, stiffness | Glass, carbon, aramid (Kevlar) |

| Plastic Matrix | Holds fibers, shapes product | Epoxy, polyester, vinyl ester |

Some people confuse FRP with Factory Reset Protection, which is a security feature in Android phones. That FRP protects your phone’s data. Totally different. We’re talking materials here—fiberglass reinforced plastic, not smartphone locks.

The idea of combining fibers and plastic dates back to the early 1900s. The first synthetic plastic—Bakelite—was created in 1907. Later, in the 1930s, engineers started reinforcing plastics with glass fibers. This combo gave them a strong, durable, and lightweight material.

By the 1940s, FRP was flying in aircraft, floating in boats, and eventually rolling into cars. Mass production took off. It kept getting better. Today, it’s everywhere—from power plants to playgrounds.

FRP has two key parts:

Fibers: Give it muscle.

Plastic matrix: Holds it all together.

Fibers come in different forms—chopped mats, woven fabrics, or fleece. The plastic can be rigid or flexible depending on the use.

Let’s break down the types of plastic used:

Thermosets: These harden once and don’t melt again. Common ones include epoxy, polyester, and vinyl ester.

Thermoplastics: They melt, mold, and reset again. Think of plastic bottles or food containers.

Elastomers: Flexible and stretchy. Good for seals and gaskets.

| Type | Key Feature | Used In |

|---|---|---|

| Thermosets | Hard, heat-resistant | Boats, aircraft, structures |

| Thermoplastics | Re-moldable, flexible | Packaging, consumer goods |

| Elastomers | Stretchy, elastic | Seals, gaskets, insulation |

There are many ways to make FRP. Here are some of the top methods:

Lamination: Layers are bonded under heat and pressure.

Wet lay-up: Fibers laid by hand, soaked in resin.

Resin Transfer Molding (RTM): Resin is injected into fiber mats inside a mold.

Pultrusion: Continuous fibers pulled through resin and shaped in a die.

Filament Winding: Fibers wrapped around a mold, cured into shape.

Vacuum Bag/Autoclave: Sucks out air, applies heat and pressure.

Chopper Gun (Spray-up): Chopped fiber mixed with resin and sprayed into a mold.

Each method fits different product types, shapes, and strength needs.

Here’s why engineers love FRP:

High strength-to-weight ratio

Rustproof and corrosion resistant

UV and chemical resistant

Low heat transfer (great insulator)

Custom colors and finishes

Non-conductive—safe around electricity

It’s not just strong—it’s smart:

Takes impacts without breaking.

Cuts and drills easily.

Lasts for decades with little wear.

Easy to repair or modify.

The most common type. It’s strong, cheap, and good for most uses.

High-performance. Lighter than aluminum, stronger than steel. Used in planes, race cars, sports gear.

Tough, heat-resistant. Used in bulletproof vests and race suits.

Sometimes, FRP gets boosted with fibers like:

Basalt – good fire resistance

Wood or paper – for eco-friendly options

Boron – great stiffness

Hybrid blends – for mixed performance

FRP shows up in all sorts of places:

| Industry | FRP Products |

|---|---|

| Aerospace | Panels, wing parts, interiors |

| Automotive | Pedals, dashboards, bumpers |

| Marine | Boat hulls, decks, covers |

| Construction | Window frames, rebar, wall panels |

| Energy | Pipes, ladders, tanks |

| Architecture | Façades, skylights, insulation |

| Medical | MRI-safe parts, mobility aids |

It’s strong, moldable, and reliable. Perfect for tough environments.

Engineers also use FRP to fix or upgrade buildings and bridges. Wrapping beams, columns, and slabs boosts their load strength.

There are three main methods:

Side bonding – FRP on one or two sides.

U-wrap – Covers bottom and sides of a beam.

Closed wrap – Full wrap for columns or full access beams.

It’s a cost-effective way to reinforce concrete without tearing down structures.

Here’s why many switch from metal to FRP:

Up to 80% lighter than steel

Won’t rust or corrode

Cuts maintenance costs

Saves fuel in vehicles and planes

Can be molded into complex shapes

Insulates against electricity and heat

| Material | Weight | Rustproof | Moldable | Maintenance Cost |

|---|---|---|---|---|

| Steel | Heavy | No | Low | High |

| Aluminum | Light | Yes | Medium | Medium |

| FRP | Very Light | Yes | High | Low |

FRP isn’t perfect. A few things to watch out for:

Hard to recycle – Most can’t be melted and reused.

Brittle if mishandled – Can snap under certain stresses.

Fiber orientation matters – Poor design can cause weak spots.

Designing FRP parts requires planning. Fibers must line up with the expected forces.

The answer is—it’s improving.

Today, FRP has challenges. It doesn’t break down. Most can’t be recycled like metals. But there’s progress.

New tech uses bio-based resins and UV-degradable plastics. Some waste FRP gets used in cement kilns as filler material. It's not perfect—but it's moving forward.

FRP = Fiberglass Reinforced Plastic or Fibre Reinforced Polymer

Yes. Fiberglass is the fiber. FRP is the finished product.

Mostly no—but new bio-resin tech may change that.

Decades. It resists rot, rust, weather, and wear.

Absolutely. It's strong, durable, and lightweight.

It means Factory Reset Protection, a security feature. Not related to fiberglass.

So, what does FRP stand for? It’s not just a name. It’s a high-performance material shaping everything from buildings to boats.

Fiberglass Reinforced Plastic is strong, light, corrosion-proof, and full of possibilities. As industries grow and new materials emerge, FRP remains a top choice. Whether you're building a bridge or a kayak, it delivers reliability, strength, and value.

Keep an eye on it. The future of FRP includes better sustainability, new resins, and even smarter design systems.

Want to see how FRP fits your project? Request a sample, or speak to our materials expert today. Explore products, compare specs, and get a solution built to last. Don’t wait—make your next move with fiberglass reinforced plastic.