Views: 0 Author: Site Editor Publish Time: 2024-02-22 Origin: Site

Introduction:

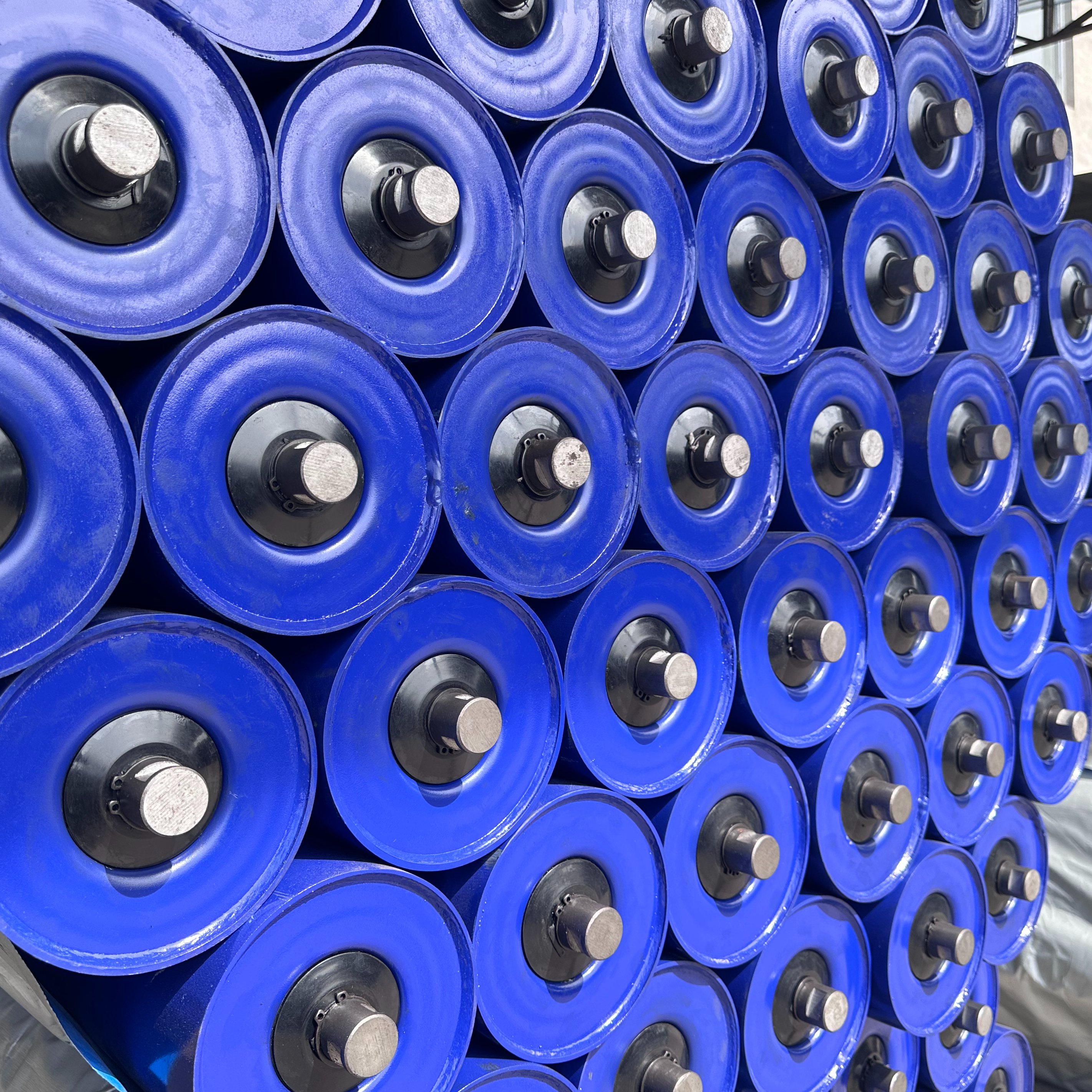

In the ever-evolving landscape of industrial manufacturing, optimizing efficiency and precision is paramount. One integral component that plays a pivotal role in achieving these goals is the use of industrial rollers. These seemingly simple devices have proven to be indispensable in various factory settings, contributing significantly to streamlined processes, increased productivity, and improved overall performance. This blog explores the advantages gained by incorporating industrial rollers into the machinery and workflows of manufacturing facilities.

1. Material Handling Efficiency:

Industrial rollers are designed to facilitate the smooth movement of materials within a factory setting. Whether it's conveying raw materials to production lines or transporting finished products for packaging, the use of rollers significantly enhances material handling efficiency. Rollers can handle a diverse range of materials, from heavy machinery components to delicate goods, ensuring a seamless and reliable transfer process.

2. Reduced Friction and Energy Consumption:

One of the key benefits of industrial rollers lies in their ability to reduce friction during material transport. Traditional conveyor systems may generate higher levels of friction, leading to increased wear and tear on machinery and higher energy consumption. Rollers, especially those equipped with precision bearings, minimize friction and, as a result, contribute to energy savings. This reduction in energy consumption not only lowers operational costs but also aligns with environmentally conscious manufacturing practices.

3. Flexibility and Adaptability:

Industrial rollers come in a variety of designs and configurations, making them highly adaptable to diverse factory environments. Whether it's gravity rollers for simple, gravity-driven material movement or powered rollers for more complex and controlled processes, the versatility of rollers allows for customization to meet specific production needs. This adaptability ensures that factories can easily integrate rollers into existing systems or deploy them in new setups without significant modifications.

4. Enhanced Precision in Manufacturing:

In precision manufacturing processes, accuracy is non-negotiable. Industrial rollers contribute to enhanced precision by providing a stable and controlled environment for material movement. This is particularly crucial in applications such as assembly lines, where components must be precisely aligned for seamless integration. The smooth and controlled motion provided by rollers helps prevent misalignments and errors, ultimately improving the overall quality of the manufactured products.

5. Minimal Downtime and Maintenance:

Compared to traditional conveyor systems, industrial rollers often require less maintenance. Their simple design, coupled with durable materials and construction, reduces the likelihood of breakdowns and malfunctions. This results in minimal downtime, allowing factories to maintain consistent production schedules and meet demand without unexpected interruptions. The lower maintenance requirements also contribute to cost savings over the long term.

Conclusion:

In conclusion, the advantages gained by using industrial rollers in factory settings extend far beyond their seemingly straightforward design. From enhancing material handling efficiency to reducing friction, improving precision, and minimizing downtime, industrial rollers play a crucial role in optimizing manufacturing processes. As industries continue to evolve, the incorporation of these versatile devices will likely become even more prevalent, driving increased productivity and efficiency across the factory floor.

content is empty!